Description

Description:

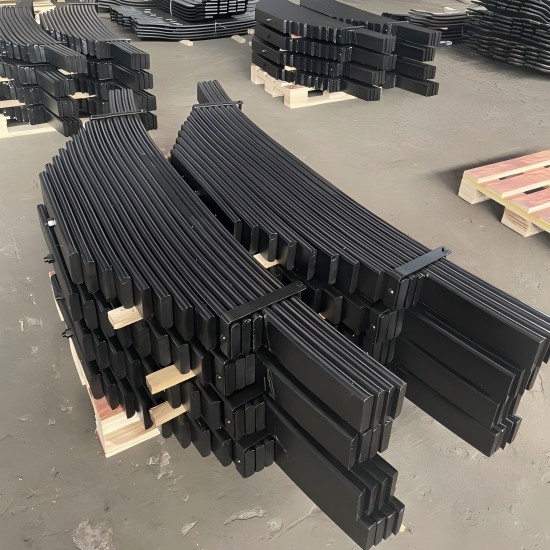

With the continuous advancement of science and technology and the development of the semi-trailer industry, the design and manufacturing technology of leaf springs are also constantly innovating and improving. In the future, with the application of new materials, new processes and the development of computer-aided design, the performance and service life of leaf springs will be further improved.

At the same time, in order to meet the increasingly stringent environmental protection and energy-saving requirements, new and environmentally friendly leaf spring materials and designs will also become hot products. Ycc Machinery Equipment Factory is a professional manufacturer and exporter of semi trailer accessories, such as: axles, suspensions, leaf springs, container twist locks, etc. for sale.

In most cases, leaf springs are placed vertically and consist of many spring steel sheets of varying lengths. When the vertical load on the leaf spring is positive, each leaf spring is deformed by force and tends to arch upward, which plays a role in alleviating and reducing the impact on the vehicle.

High quality steel leaf springs for sale

High quality steel leaf springs for sale

Brand new leaf spring with best factory price

Brand new leaf spring with best factory price

China’s leading semi trailer spare parts supplier — Ycc Mech

China’s leading semi trailer spare parts supplier — Ycc Mech

Precautions:

1. Pay attention to the maintenance of leaf springs. Grease for the leaf lugs is essential. The upper limit of the auxiliary steel also needs more grease, which can reduce abnormal noise while playing a lubricating role. At the same time, it can also make the steel plate more relaxed when the friction coefficient is increased. Dryness will increase the phenomenon of steel sheet surface strain and increase the possibility of steel sheet breakage.

2. In addition to the lubrication of leaf spring components, pay attention to the tightness of the riding bolts and center bolts that fix the leaf springs in daily maintenance to avoid loosening of the riding screws, which will cause the entire set of leaf springs to fail and even threaten driving. Generally, the higher the load of the vehicle, the more frequent the inspection.

3. The number of leaf springs depends on the load of the vehicle, so don’t think that the rigidity of the leaf spring is large and you can do whatever you want. When the vehicle is often overloaded or the center of gravity is biased, you have to consider increasing the force of the leaf spring to enhance the overall service life.