Description

Features:

The axle is also called the axle assembly, which consists of the brake base plate, spherical bearing seat, air chamber seat, etc. Then on the basis of the shaft assembly, the camshaft assembly, brake assembly, wheel end assembly, cotter pin, adjustment arm, ABS sensor and other components are installed.

25 ton heavy duty American axle has both ends connected to the wheels through wheel end assemblies, and the middle is connected to the frame through the suspension system. The top of the frame is the main location for cargo loading. Therefore, the heavy-load performance of the axle directly determines the load-bearing capacity of the semi trailer.

From the perspective of processing technology, the American axle uses a one-piece shaft body forging process. That is, the shaft heads at both ends are integrated with the shaft tube in the middle. They are both ground directly from a steel pipe, and the load capacity is relatively high.

25 tons heavy duty American semi trailer axle

25 tons heavy duty American semi trailer axle

High quality trailer axles for sale

High quality trailer axles for sale

Factory lowest price American axles near you

Factory lowest price American axles near you

Advantages:

The axles we provide are all made of high-strength alloy seamless steel pipes as raw materials. They undergo multiple production processes such as 1300°C hot rolling, 865°C intermediate frequency quenching, 480°C insulation tempering, multi-point online straightening, precision grinding and other production processes to fully guarantee the axles. strength, toughness and durability.

We are a professional axle manufacturing factory with advanced production lines and processing technology, leading in production efficiency and technology. Can meet your various usage needs, and provide customized services for special sizes and specifications.

The axle body and components are designed using North American standards, and the interchangeability of components can reach 100%. Each model of axle product can be equipped with an ABS system. The braking system is more sensitive and the use process is safer and more reliable.

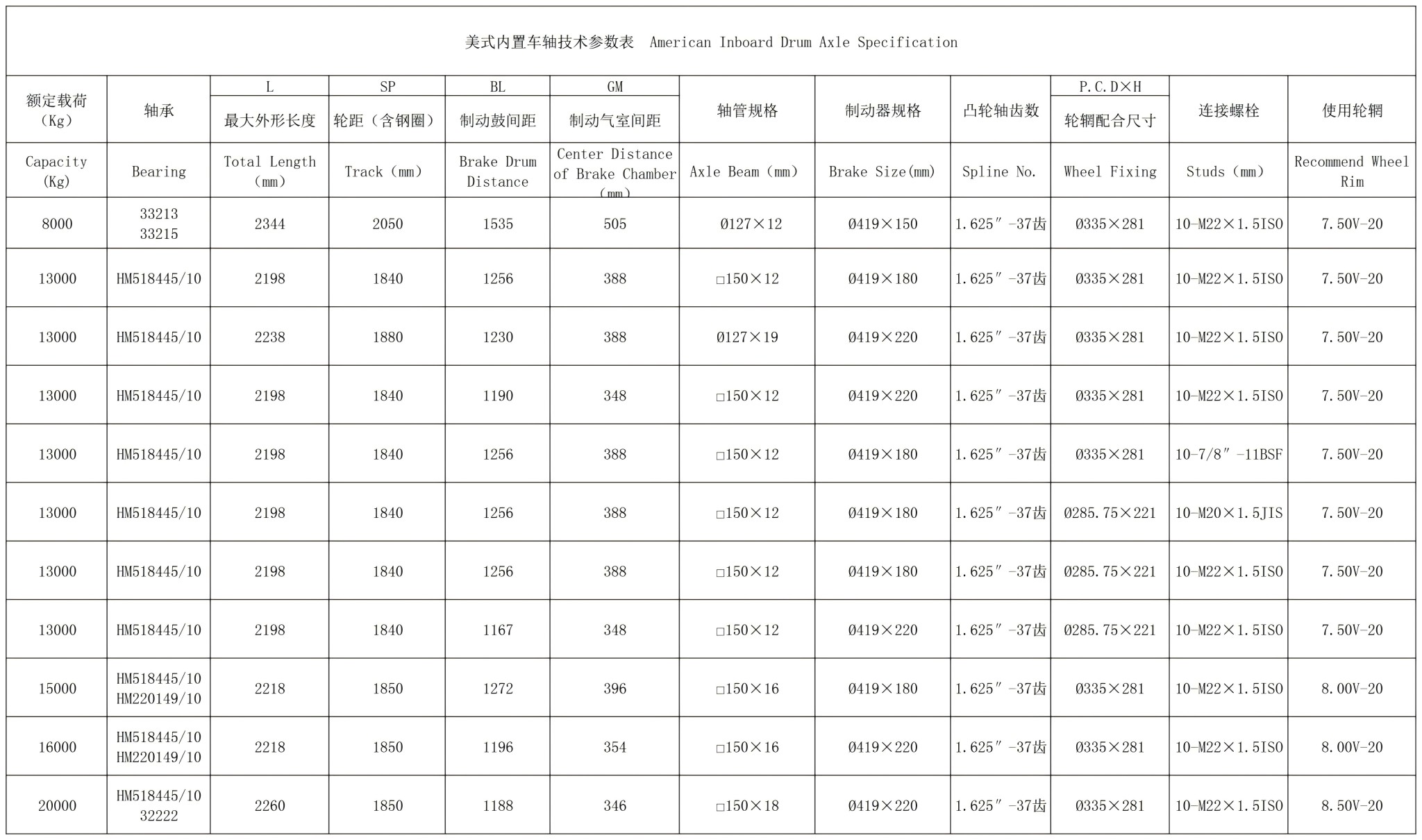

Specification: